Drying time is an important variable in the process of processing dried fruits, vegetables and nuts. This has a direct impact on the quality of the finished product, in addition to impacting the production capacity, because the longer the drying is the less it is produced. This time varies according to the nature of the food and the characteristics of the dehydrator used. There is no magic recipe to determine the drying time evenly and accurately. One of the challenges of the transformer is to obtain a uniform result while optimizing the quantity produced and limiting the human interventions that are sources of errors.

Upon arrival at the factory, a fresh fruit contains 80 to 90% water. It is dry and ready to use or bagged when its water content is 15 to 30% depending on the type of food. The high temperature of the air in the dryer (typically between 50 and 100 degrees Celsius) and the circulation of the latter causes the reduction of the water content of the food. There is therefore a relationship between the temperature and the drying time necessary to lower the water content of the fruit to the desired level. In principle, the drying time can be determined according to the nature of the fruits (variety, maturity, size), and according to the characteristics of the dehydrator used (arrangement of trays, air flow, uniformity of temperature). However, in practice too many variables are taken into account and the drying time departs from that calculated theoretically. Plants will instead set the temperature according to the type of food and determine the drying time empirically, that is to say by performing test rounds during which the fruit will be removed from the dryer periodically to measure the content in water manually. The ISO 665-2000 standard offers different measurement methods based on mass loss or moisture measurement. These manually taken measurements represent a considerable amount of work and require qualified personnel. Also, they require several times the temporary interruption of drying. The determined drying time does not take into account these interruptions, which generates a certain error. Once the drying time has been determined for a new food, the plant is finally ready to process the one at higher volume.

During preparation, the drying time is used to program the dehydrator timer. In this way, the dehydrator will stop automatically and often employees will be alerted by a sound tone. Here is an example of a frequently used controller, the H5CX by Omron.

Source : https://industrial.omron.ca/fr/products/h5cx

Unfortunately, slight variations in the raw product (for example, its initial water content) may affect the final result. This is one of the main weaknesses of this method or the cooking time is predetermined.

There is currently a craze for local and organic foods. Since one of the most effective ways to preserve fruits and vegetables while preserving their properties is to dehydrate them, it is not surprising to see new dehydration plants. A good example is the Anhydra plant in Quebec, which, in addition to its wide range of in-house products, offers dehydration outsourcing services and the creation of private labels for its customers, which pushes it to be more flexible and adapt quickly to new products.

When it comes to dehydrate in small quantities, mills face the challenge of having to quickly adapt the drying parameters (time and temperature) to the new food, while minimizing losses and shutdowns. The large factories are not immune to this new reality 4.0 that wants to adapt quickly to the demand and the raw material offered on the market.

A key part of the solution is to multiply the measurement points to better control the process, even in the presence of a food for which the optimal parameters are unknown. But more measures and tighter control mean more work for the plant. Many factories are turning to instrumentation with internet-based sensors and web technologies to automate the measurement, analysis, control and monitoring of their processes. Web software offers more flexibility than traditional software on computers or programmable logic controllers, in addition to being able to manage larger amounts of data and be more easily interfaced with each other. These plants, small or large, are called 4.0 plants.

Indeed, a new trend among more experienced dehydrators is to continuously measure the humidity of the ambient air inside the dehydrator and use this measure to control the dehydration time, that is to say stopping the dehydrator when the air is almost empty of moisture, for example at 5%. We therefore rely on the correlation that exists between the water content of the food and the humidity of the air around it. Rather than manually measuring the evolution of the water content of a new food product that has never been produced, the humidity of the ambient air is observed more continuously and automatically thanks to the addition of a sensor, so without any intervention. human and without contact with the product. The ultimate goal is the dehydration of a new food without performing a priori test. A humidity sensor is installed at the tank and connected to the internet. This sensor will measure the humidity permanently and make the data available to a web service which will in turn control the relay that controls the power supply of the heating elements of the dehydrator. The dehydration time adapts itself each time thus guaranteeing an optimal result. Ideally, this sensor will be wireless and battery-friendly, greatly simplifying installation. Here’s an example of a sensor using an ultra-long-range wireless standard ideal for all sizes of plants offered by Altus. This sensor tolerates high temperatures up to 125 degrees Celsius.

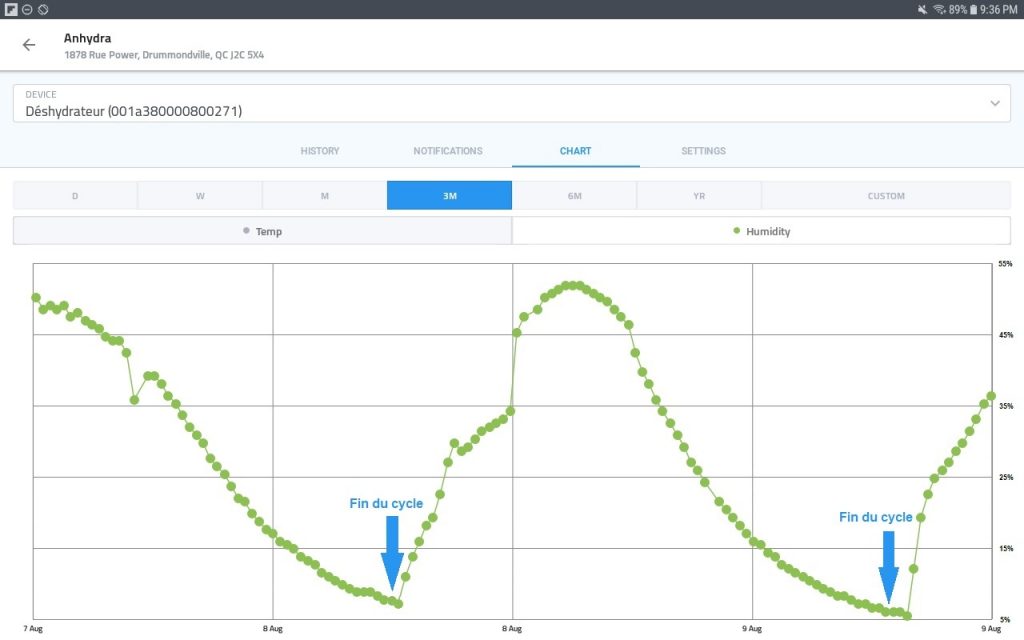

In addition to monitoring humidity in real time and controlling the dehydration cycle, plant staff will be able to consult the history of their past productions for traceability and quality control purposes. The following image shows the Altus web or mobile application. There are two drying cycles interrupted when the ambient air has reached 6% humidity.

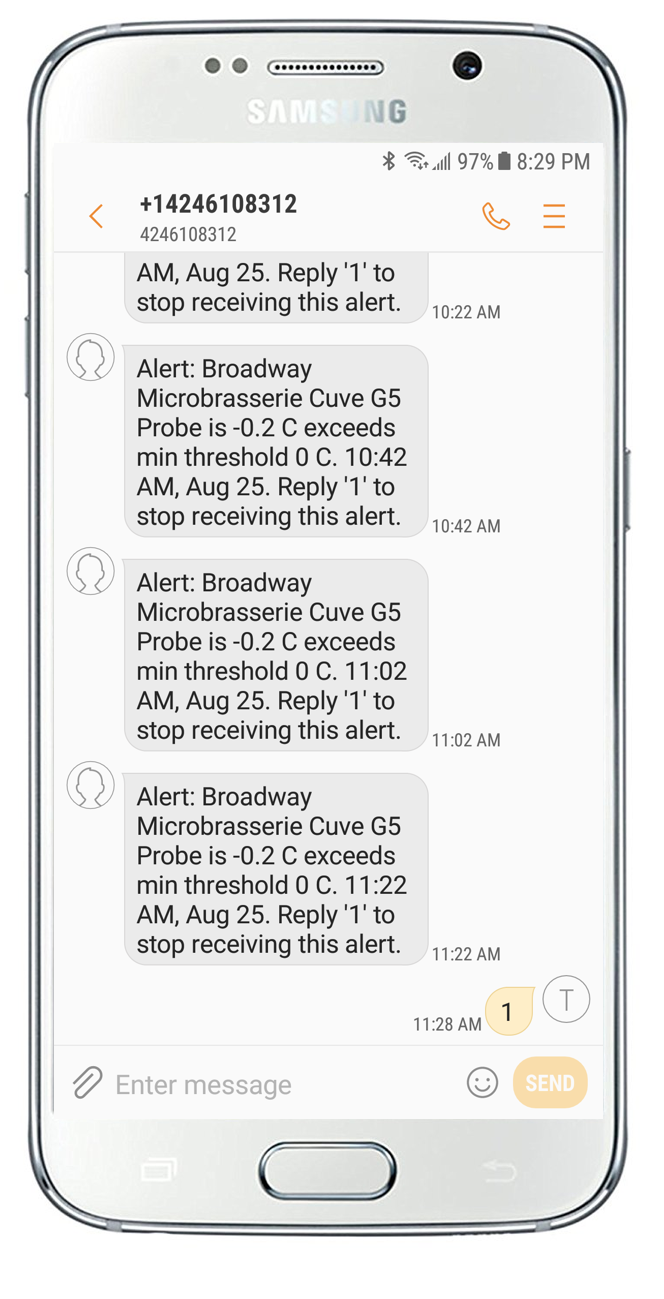

The most advanced systems will offer additional features such as email alerts or SMS. For example, receiving an alert when the minimum moisture threshold is reached and dewatering is complete. Alerts can also be used to report abnormal situations, such as stagnant humidity or abnormal temperature. Such alerts free employees from the need to check your dehydrators periodically, leaving this responsibility to the system that will alert them by email or SMS when needed.

To conclude, the humidity of the ambient air reveals information on the variation of the moisture content of the food being dehydrated. The use of this information to control the dehydration cycle rather than a fixed duration is aimed at eliminating the phase of empirical testing that would otherwise precede the high volume production phase. This inexpensive addition allows plants to adapt their production faster to changing demand.

In more modern plants, technologies such as the web and long-range wireless sensors automate measurement and analysis, freeing employees from certain repetitive tasks, minimizing errors and losses, while maximizing production .

You work in the field of food processing and want to optimize your operations without spending too much? Contact us and it is with pleasure that we will help you.