Whether you work at a Municipality, an Oil Rig, or a Food Processing Plant, you know how important remote monitoring of your operations is! A Supervisory Control and Data Acquisition System (SCADA) usually fulfills this function of remote monitoring for your facility.

What is SCADA?

A SCADA is a distributed remote management system that allows many measurements to be processed in real time as well as to control industrial processes in the field. Communication between the SCADA software and the equipment in the field is usually wired, either by Ethernet or Optic cabling. Though we use we use wireless devices in the car, at home and in the office, wireless has not taken off as mode of communication in Industrial applications in a big way. Have you ever wondered – why, not? Are SCADA and wireless compatible?

Is the IoT real?

The number of devices connected to the web is currently estimated at 20 billion and will reach 80 billion by 2025. In Canada, the manufacturing sector would be the most impacted ahead of health, transportation, and the agricultural sectors. Smart devices and Artificial Intelligence are entering the factory floors and need to merge with the industrial systems that currently ensure the smooth running of production, in what many describe as the 4th Industrial revolution (or Industry 4.0).

Inevitably, such a proliferation of the number of devices connected to the web is based on the use of wireless (as a means of communication) and batteries (as a source of energy), otherwise the wiring and installation cost to connect such a number of devices would make application of IoT cost prohibitive. So yes, IoT is real, but only with wireless!

SCADA’s interface to the physical world

Several implementations of SCADA software exist and they usually include a middleware to manage communication with different devices deployed in the field such as Sensors, Programmable Logic Controllers (PLC), graphical interfaces used by operators (HMI) as well as various other types of industrial machines and instruments.

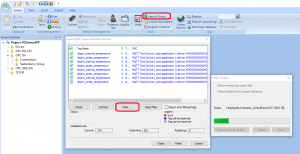

Image: Example of a SCADA software: Indusoft by Aveva / Schneider Electric.

CAN, EtherCat, ModBus, ProfiBus, BacNet, HART, MQTT; these are just a few examples of dozens of communication standards that exist. A more exhaustive list where the communication standards are categorized by fields of application is available on Wikipedia. Each SCADA solution typically supports only a fraction of these different protocols. Therefore, the selection and adoption of one SCADA solution for your plant limits the communication standards offered to connect the equipment on the shop floor.

Nowadays providers of SCADAs and PLCs come together and adopt a common format to enable interoperability. The latest protocols mostly leverage the suite of Internet IP protocols while defining an application layer on top for the exchange of industrial data. An example of a common format (and probably the most used) would be OPC-UA. The OPC is an Industry consortium that creates and maintains standards for Open Connectivity of Industrial Automation. This Open Connectivity Standard is crucial for Industry 4.0.

How to connect any data source to your SCADA

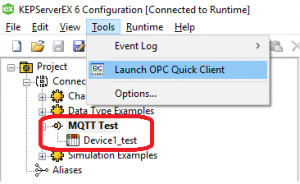

You can now find connectivity platforms that provide a single source of industrial automation data to all your applications. Based on our research, the leading provider of connectivity platform is Kepware’s KEPserverEx (by PTC) which includes an OPC-UA server with connectors for more than 140 communication standards from the world of industrial automation and IT. KEPserverEx allows potentially millions of different devices to be connected together and to the cloud (here’s the list of communication standards supported). The data is converted into OPC-UA tags – and optionally MQTT – available to any OPC-UA/MQTT client on the network or on the Internet by extension.

Image: creation of an MQTT channel in KEPserverEx 6. The data is also converted into an OPC-UA tag available to any OPC-UA/MQTT client on the network.

Bridging the gap between OT and IT

A major trend nowadays in the Industrial Internet of Things and the Industry 4.0 is the convergence of industrial systems aka Operational Technology (OT) to the enterprise systems aka (Information Technology (IT). The objective is for industrial applications to benefit from the latest information technology, such artificial intelligence and serverless computing. While there is benefit in getting the data out from OT and make it available to IT, the inverse of applying the knowledge derived from the IT world and sending it back to OT is also important. The IT technology is generally available as “Web Services”. Companies need to leverage the “Web Services” to superpower their operations in order to stay competitive in Industry 4.0.

Altus is bridging that gap today using technologies borrowed from IT and telecommunication for bringing massive data from the shop floor into existing PLC and SCADA systems. The company has set itself the task of exploiting long-range (10 km+) wireless, such has LoRaWAN and 5G, to enable remote monitoring and assisted decision-making in industrial processes. Altus serves the industry at large, and offers more targeted solutions to the food sector (link to Altus’ Temperature 360 solution).

Image: Altus long-range (10 km+) and customizable wireless sensor

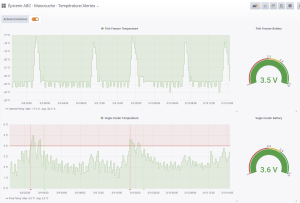

In order to be on the cutting edge of technology, Altus has opted for MQTT as the communication standard offered with its web application. Although it is possible to view your sensor data directly in the Altus standalone web dashboard (offered on the Cloud and on-premise optionally), it is also possible to send your wireless sensor data directly in a SCADA software by using KEPserverEx thus closing the loop and enabling “continuous improvement”. Altus offers the integration of a customizable long-range wireless sensors with the SCADA software of your choice. A demo of Altus web dashboard is accessible here.

Image: Altus standalone web dashboard (offered on the Cloud and on-premise optionally)

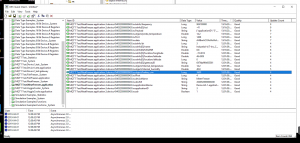

The image below shows data from Altus’ sensors. The MQTT data is sent to the OPC-UA KEPserverEX 6 server from which it is available to any OPC-UA client on the local network or on the Internet by extension. The data can also be translated into more than 140 communication standards for sending to other non-OPC-UA compatible devices such as PLCs and SCADA software.

Image: MQTT data from Altus’ long-range wireless sensors sent to the KEPserverEX 6 server to any OPC-UA or non-OPC-UA devices.

The next image shows sensor data sent to the Indusoft SCADA. MQTT data passes through KEPserverEX 6 and is converted to OPC-UA to which Indusoft then subscribes.

Image: Data from Altus’ sensors in Indusoft SCADA via OPC-UA.

By the same token, we have demonstrated how it is possible to make the bridge between the world of industrial automation and SCADA, and that of objects connected to the web wirelessly (internet of things).

Are you interested in connecting sensors to the Internet in an industrial context? Do you want to know more about the possibility of using long-range wireless (10 km +) in your projects? Please do not hesitate to contact us.