Controlled Refrigerated Warehouse Temperature means Food Loss Avoided

Sobeys Inc. is one of only two food retailers operating across Canada, with more than 1,500 stores under various banners, such as IGA, Bonichoix, Marchés Tradition, and Voisin, whose mission is to meet the grocery needs of its customers.

A Sobeys warehouse can house a multi-million dollar food inventory. Therefore, the temperature must be strictly controlled to protect the perishable foodstuffs. To ensure the proper functioning of the refrigeration equipment and the correct temperature of the food, employees must physically visit the various warehouses and measure the temperature several times a day, 7 days a week.

Reduced Staff and Limited Human Resources

During an unforeseen period of disruption, Sobeys was forced to operate with reduced manpower. Because the human resources to carry out the temperature controls in the warehouses were limited, it was difficult, if not impossible, to cover all the time periods, particularly during evenings and weekends.

Maintain Monitoring of Refrigeration Systems

In order to not overload and further exhaust the members of the quality control team, urgent action was required. Leaving the food unattended was not an option. The consequences of a major temperature difference would be catastrophic for the company. Indeed, since a temperature deviation usually results in food loss, and, consequently, in important financial losses, the monitoring of the refrigeration system had to be maintained. But, how could this be done in such a way to ensure that any change in temperature could be noticed and addressed quickly enough to avoid food loss?

Search for an Economical and Efficient Remote Monitoring Solution

Sobeys wondered if there was a more economical and efficient way to measure the warehouse temperature instead of physically sending people to the refrigerated locations to take measurements. They realized that they needed a remote monitoring solution to control the temperature of their refrigerated warehouses.

Selection Criteria and Requirements

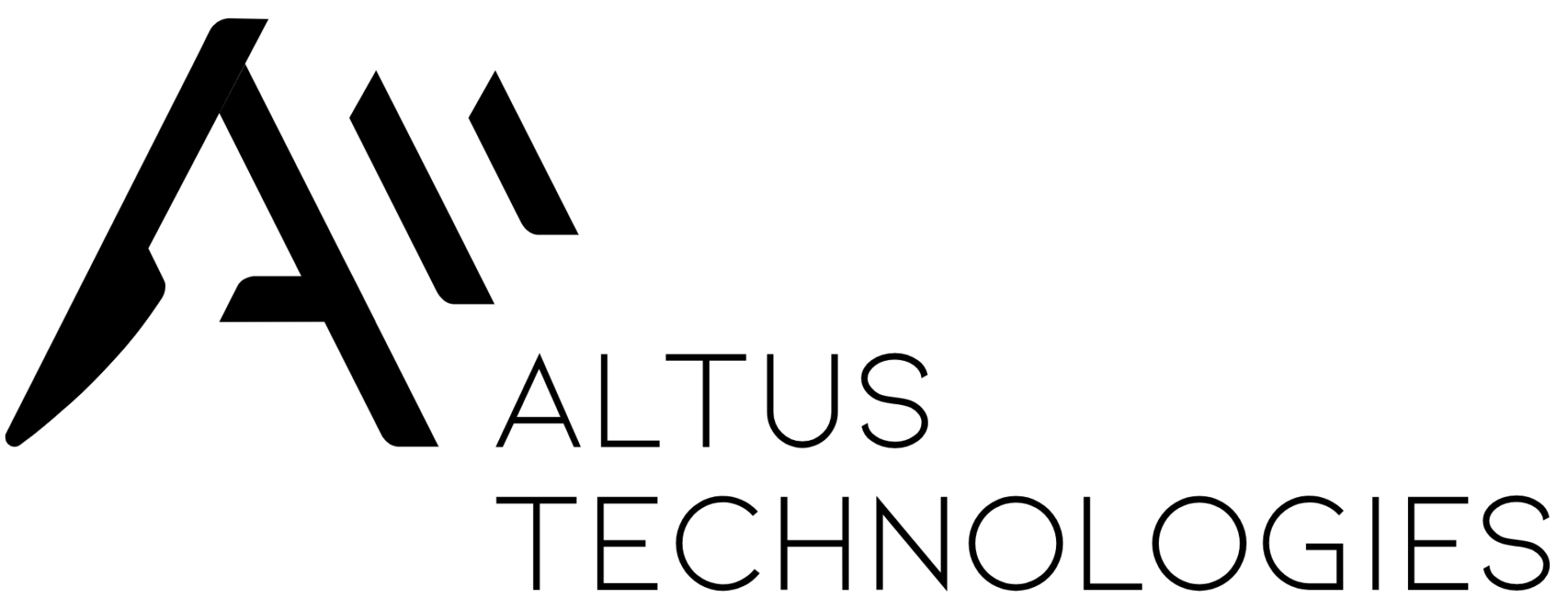

Sobeys established their selection criteria in order to choose the monitoring solution that best suited their needs. The required solution had to be quick to install—ideally within a few hours—and simple to implement so that the quality control team could use it immediately. In addition, the chosen solution had to allow for remote, real-time access to temperature data, thus offering continuous visibility. The selected solution also had to alert the quality control team anywhere and anytime if temperatures crossed a well-defined threshold. Moreover, it had to not only control the temperature of the warehouses but also monitor the ripening process of bananas. Finally, this simple and efficient solution had to be cost-effective and include quality service within reasonable proximity.

Installed Solution and Operational System (in 3 hours)

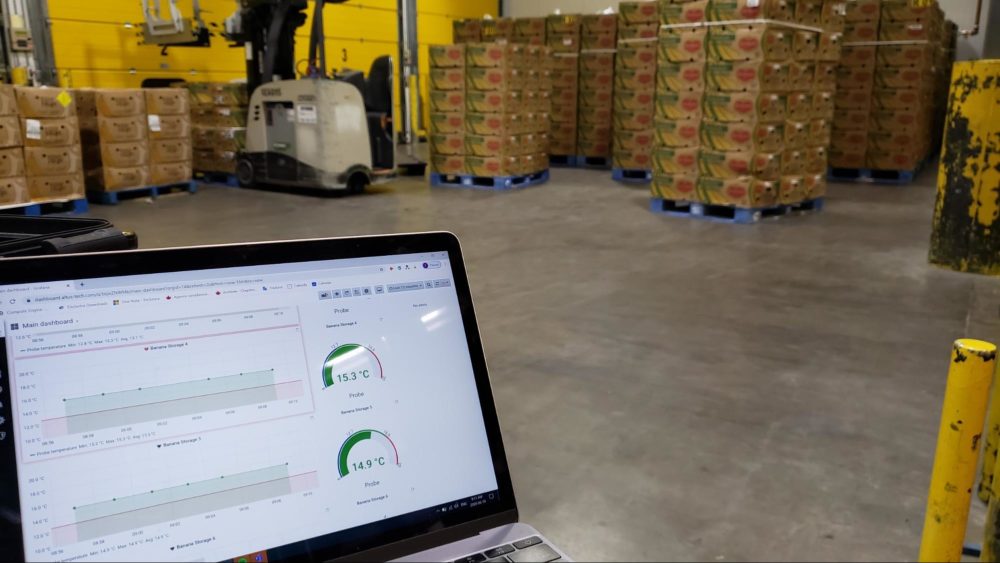

This is how Altus Technology’s Temperature 360 sensors made their debut at Sobeys. Without hesitation, the company opted for this wireless technology and acquired waterproof and resistant sensors powered by batteries. Because no power supply wires or wired communications networks were required, the installation was completed in less than three hours. Indeed, the system was operational by noon on the same day. Moreover, since the Temperature 360 sensors use an ultra-long-range LoraWAN wireless network, the data reception was guaranteed everywhere in Sobeys’ warehouses.

Instant Alerts

Altus Technology’s Temperature 360 sensors eliminated the need to send an employee to the warehouses to take the temperature measurements manually. In fact, since the data is transmitted in real-time, quality control can consult it continuously, anywhere, and at any time, even during power and Internet service outages. Most importantly, they can be alerted by text message or instant call in the event of temperature deviations.

Affordable Price

Finally, the affordable price of the Temperature 360 sensors, as well as the free software, convinced Sobeys that the temperature monitoring solution offered by Altus Technology was the right one for them. Sobeys acquired the solution through Cimco, one of the three largest refrigeration companies in Canada, which also installed the sensors in their warehouses.

Cloud Platinum Plan

Initially, Sobeys chose to use Altus Technology’s option-to-buy lease solution rather than purchasing the solution outright. This option allowed the company to solve their issue very quickly, without waiting for the entire budget cycle, which was required to obtain approval for the purchase. Also, Sobeys chose the Platinum Cloud plan, which offers the following: (1) temperature readings every minute, (2) data retention for a period of 7 years, (3) an unlimited number of users, (4) a dedicated account administrator available 24/7, (5) a guarantee on the quality of service that offers refunds on certain sums if the system breaks down, (6) data synchronization with DataHex PaperLess, a quality assurance software used by, among others, St-Hubert, Coca-Cola, Plaisirs Gastronomiques, and Première Moisson.

An Immediately Profitable Solution

Two alerts were detected within the first month of use. Thus, Sobeys was able to avoid losses of tens of thousands of dollars in perishable food. These avoided incidents, thanks to the excellent functioning of the Temperature 360 sensors, enabled Sobeys to save well beyond the cost of the solution

Food Losses Avoided

The entry of Altus Technologies into Sobeys’ warehouses has helped preserve hundreds, possibly even millions, of dollars in inventory. The company was able to avoid food losses while limiting the physical presence of employees in the warehouses to emergencies only. The alerts emitted by the Temperature 360 sensors have also revealed to the quality control people that incidents happen more frequently than they thought and that the investment in such a fast, simple, and effective remote monitoring solution has an important return on investment in the short term.

In short, Sobeys now has the peace of mind that Altus Technology’s Temperature 360 sensors wisely control food temperature.

Get Pricing

Integrate a partner’s sensor or even a custom-made sensor.